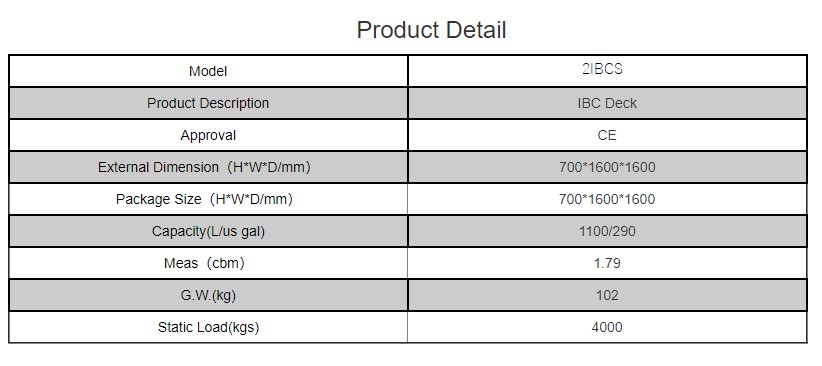

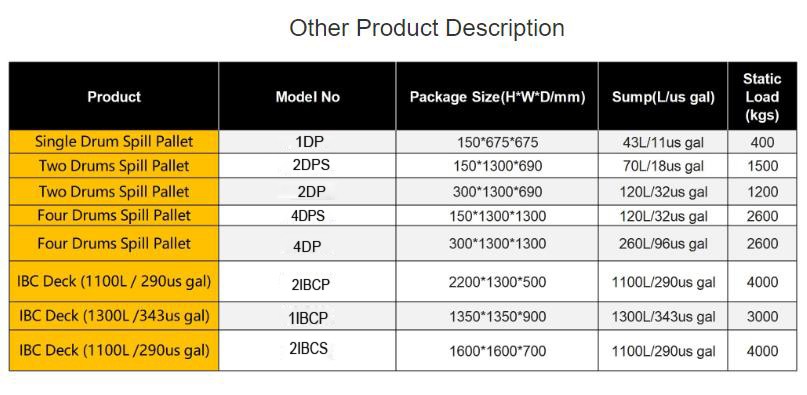

IBC Spill Pallet 2IBCS

THC Oil Drum Leakage Tray

The leakage tray adopts a rotary forming process and is formed in one go. This pallet has the characteristics of sturdy structure, forklift operation, anti slip, and strong applicability. When leakage or overflow occurs during the distribution process, all leaked liquid will automatically flow along the tray or platform grille into the tray or platform. In the leakage area of the platform (leaking storage tank), it will not flow to the ground, corridors, or channels, polluting the on-site environment, causing occupational accidents such as falls and falls, and also preventing soil and water pollution. There is no need to worry about accidental splashing and leakage of hazardous chemicals during packaging or storage.

It complies with the US Environmental Protection Agency (EPA) EPA 40 CFR 264.175 and SPCC regulations, as well as the US National Pollution Elimination and Emissions System (NPDES), and has passed EU CE certification.

It complies with the US Environmental Protection Agency (EPA) EPA 40 CFR 264.175 and SPCC regulations, as well as the US National Pollution Elimination and Emissions System (NPDES), and has passed EU CE certification.

Tel:

Tel:

Email:

Email:

Fax:+86-755-27808698

Fax:+86-755-27808698

Address:

Building D, Bao'an Zhigu, Xixiang Street, Bao'an District, Shenzhen City, Guangdong, China.

Address:

Building D, Bao'an Zhigu, Xixiang Street, Bao'an District, Shenzhen City, Guangdong, China.